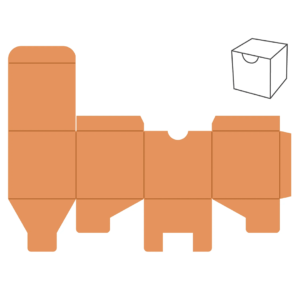

Die Cutting

Printing Bobst die cutting processes are among the most common printing operations. It is very important to achieve consistently high shell quality on an industrial scale. Together with the brand new BOBST die cutting machine we have created a complete cardboard converting line. We continue to offer the best use for folder gluing on the market today. BOBST, which is a special machine type with the possibility of gluing product boxes together with folding, offers error-free operation. Among the services we provide in printing works, the printing press pedal cutting process is among the most preferred ones.

It cuts all kinds of cardboard, corrugated cardboard, plastic sheets and leather materials very precisely and reliably. For this reason, it offers the opportunity to be used as a first class machine. While the die cutting machines are working, the printing machine with heidelberg boiler can also be preferred. In some segments, consumables are subject to change in terms of other possible factors. It has a broad-footed structure with a thick bar. It does not cause loss of time by performing cutting operations quickly. It offers serial cutting opportunity with its professional working system.

Cardboard packaging cutting machines, which also offer cutting features in accordance with paper cardboard types, perform a functional operation. When the box is placed in the mold manually, the machine can wrap the box automatically. It is adjusted to fold the corner edge. With its structure that can shape the box, it can press the balloon in the same order. There is no need to change the press plate and pusher when changing dies. It just can automatically adjust the length, width and height of the box to reduce the time to change the mold. In this way, it increases mold control steps and product efficiency.

Offset Printing Quality in Cardboard Boxes

Offset printing, which is among the printing works, offers high performance in preparing, gluing and cutting all kinds of product boxes. The desired speed can be adjusted by manual operation thanks to the manual feed cutting of the printing press. It is an important process where the relief is applied using a cliché. As the sheet is gilded, special types of clichés can also be used for embossing. We are preparing as MC Cellophane Printing Packaging , which reveals the offset printing quality in every material. The desired speed setting is also available for cutting many materials, with the manual rocking pedal cutting type available.

It offers frictionless operation with slide carriers. Made of copper alloy to reduce vibration. The machine body consists of one-piece casting. Thanks to its single-link electromagnetic device, it provides work in a short time. Thanks to its opening functions, it offers options such as waiting time, continuous operation. It performs flawlessly with its central lubrication system. The printing press, which has a safety system, offers high performance with rocking pedal cutting. Although it is continuous, it works with the stop-start feature. It performs fast work thanks to its automatic mold clamping apparatus.

In automatic die cutting types, fully automatic cutting with printing bobst sorting always helps to prepare in a short time. The machine with the desired paper size works without errors. It does not waste time by preparing thousands of cuts in a short time. It performs the desired cutting shape by offering optimum performance. The minimum paper length is determined as 50 cm. The maximum size option is 112 cm. It has automatic cutting machine style with sorting. In this way, it offers uninterrupted work. It provides optional counting and separating function. With its functional structure, it exhibits an error-free operation in cutting.

Cardboard Cut Types

As there are many product options, there are also cutting types in the boxing process of the products. Thanks to the cardboard packaging contract cutting, the product you want is easily cut. Many details are adjusted smoothly with the tension speed, folding and depth perception of the machine. There is a brush for pushing the corner ear in paper and cardboard cuts. It provides forward and reverse operation at the same time during operation. The cut can be adjusted according to the length of the paper corner ear. The possibility of automatic adjustment of the mold instead of being manual provides a lot of convenience. The possibility of adjusting the change time of the mold provides convenience and increases the quality by providing efficiency in production.

Among the cardboard options, the corrugated cardboard cutting process is done with the help of a special machine. It offers the possibility to adjust the machine. It is a more durable form of cardboard box made from corrugated cardboard. This material has a corrugated structure between the two outer cardboard layers. It is also used in transport boxes and storage boxes as it is more durable than cardboard boxes. Color structure may vary as well as variety.

The gray cardboard is cut and the boxes are prepared in line with the customers’ request. Gray cardboard, which is used for many materials, ensures that the products are kept in an elegant box. Gray cardboard is used in two different ways. It is used in different fields as handicraft printing machines. It has a long fiber content. It is used in similar manufacturing processes such as boxes and packaging. It is also possible to use on binding covers for books. It consists of a smooth surface. Recycled paper is preferred. It is a form of packaging that always offers a stylish look for box cut products. Grinding box models are as follows;

1-) coated paper

2-) fancy paper

3-) Fabric

4-) Skin Gland

It is prepared by drafting the specified products on hard cardboard. Boxes of care products are used according to many product ranges such as perfume, electronics, shoes, textiles. Cardboard embossing has a wide range of uses. It is a type of paper-based material that is thicker than traditional flexible writing papers. The added thickness increases stiffness and makes the material lightweight and suitable for a wide variety of products. Allows it to be used to create other packaging.

Cardboard Embossed Cut Types

It is a type of paper that offers embossing feature of cardboard embossed used in many product boxing processes. A fabric variant is also available. It helps you to achieve a functional appearance with its embossed feature. In this way, embossing can be done on many subjects for an aesthetic appearance. For the preference of cardboard seersucker, it gives a stylish stance by adding dimension to the printed and unprinted areas. It also offers the possibility of use as a cardboard embossed cliché. The embossing, which is used by making a double-sided cliché, is created by lowering it with acid. It is also prepared by the erosion method. Zinc and steel can be used for printing. The applied clichés have a thickness of 3 mm. There is also the possibility of using 5 mm in some weight papers. Clichés used in the market are of two types. One is zinc and the other is photopolymer. Although one is high and the other is low, the level of stance shows a difference. Thanks to the contract cutting in ISTANBUL, every desired cutting and packaging process is done perfectly. When the other cliché prints on the cliché that is protruding, the embossing process takes place. Thus, the desired area is embossed and an elegant appearance is obtained. MC Cellophane Printing Packaging performs contract pedal cutting works with the desired speed and flawless operation.

In our company , which cuts many materials such as cardboard, paper and fabric according to preference, various applications such as contract bob cut, pedal die cutting , packaging process, box gluing are carried out professionally. A separate machine is used for each process, and the working style of each machine varies. Many surface applications take place in the works. In this way, there is a wide range of products, but all kinds of printing works are carried out thanks to Mc cellophane printing packaging. Although it is the choice of many companies, we continue to exhibit a flawless work with the help of professionals who provide professional work.

visit our Facebook page for more information

Return to the Homepage