Hot Foil

Although hot foil is applied to the surface of the box in many packages, its integration into the product is ensured by the thermal application method. For hot foil , the cliché must first be heated. In this way, the leaf is separated from its carrier and transferred to the area to be applied. Leaf clichés offer a one-way use. In practice, metal cliché and letterpress made of lead are used. 75*105 automatic contract hot foil gilding is also used according to product preference. The foil, which creates an elegant design in terms of appearance, can be applied on many materials, especially on leather cloths. Optionally, 64 * 90 contract hot foil gilding is applied to keep the print quality at the highest level.

The most widely used printing press among offset printing types, the use of pedal hot foil provides an elegant appearance to the product structure. As it is used on many surfaces, it is very important that the foil is integrated into the desired surface during the transfer phase. Hot foil , which should be done without mistakes, can also be preferred on book covers. For example; Book covers gain a unique appearance with the application of hot foil gilding on the binding cloth. The gilded printing type used in office equipment is integrated into many product forms. Another of the most preferred applications is the hot foil gilding option of the framed box. The quality of the material used is very important in terms of durability.

Printing Applications with Hot Foil

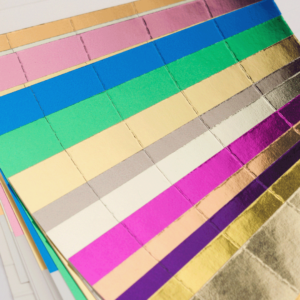

Thanks to the foil, the printing house cardboard textile labels offer a striking appearance with the hot foil gilding application. It consists of two different types during production. These are hot press and cold press. Three different types of paper are used, keeping the visuality in the foreground. Preferred papers are transparent, metallized, hologram type. It is preferred both for its appearance and for its color quality by emphasizing the product. The gilding types used are metallized gilding with gold-gilding. It can be adhered to many surfaces, including metal, plastic, glass surfaces.

Among the preferred areas, there are also types of printing on the box. Printed cardboard cosmetic boxes are just one of the types preferred in hot stamping. The usage area of the foil label is quite extensive. It exhibits a structure resistant to liquid contact. If the glass surface is to be preferred, the product should be made with the choice of plastic paper. It is prepared with a recyclable product structure. The product content exhibits a durable structure. It also resists deformation. There is no problem against abrasion in water. In this way, it is a durable label type used for many products. If it is made for the material to be used in a cold environment, it should be lacquered with cellophane.

Chocolate boxes can be gilded with hot foil in the choice of foil preferred for food products. By providing UV protection, the print quality on the product increases. It should be preferred for a quality printing type in such applications. It offers the possibility of application in various fields such as invitations, book covers, brochures, gift boxes for the use of foil. Then, the packaging application is done exactly thanks to the lacquer application with hot cellophane. Thus, the product provides durable use for a long time.

Foil Application with Hot Stamping Method

Foil application offers a widespread use in stationery products. If hot-cold printing type is used, this situation varies according to the product structure. The organizer binder cloth offers a stylish look with the preference of hot foil gilding. In application techniques, letterpress printing type prepared from lead with metal cliché is used. The gilding paper placed on the material was placed with the skin cloth placed on the material to be applied. In this way, transfer printing can be done. Various products such as powdered gold leaf, silver leaf can be used. It is a painting process in which gilding is sprayed onto a transparent printed substrate.

In some book printings, historical mosaic printing, gold, silver, copper, bronze colored powders make it easy to apply to paper prints. There are important points to be considered in foil printing. It offers a wide application area in terms of high consumption amount. Multi-colored, transition effect, screened metallic color application can also be made. Gilding can be preferred in the packaging process of nutrients. In this way, besides offering a stylish appearance, it supports the product with processes such as lacquer and cellophane. Food boxes are prepared as quantity or piece printing before the hot foil gilding processes.

It can be preferred for many fabrics such as textile, leather. In this way, it offers a wide product range. Foil is used in packaging types that offer a lively look with the use of foil. It helps the foil to pass onto the paper by giving 120 degrees of heat. When printing on film, it is important that the paper adheres to the film. First of all, glue should be applied to the fabric, the glue used should be transparent. After applying the glue to the fabric, it is sufficient to stick the foil to the fabric. The choice of fabric and color is completely shaped according to your preference. When you want to get a striking appearance, the application brings the product to the fore.

Cardboard hologram is prepared by application on hot foil gilding fabric. The boiler of the machine is brought to 120 degrees. Thus, in order to give a lively appearance, the foil is exposed to heat to pass onto the paper. This process is repeated for many materials. Attention is paid to both printing speed and quality. Although it is a difficult process, the machine used must provide rapid integration. Transfer on paper or fabric should be carried out with durable materials. Otherwise, it creates a bad image with the flow of paint. In order for the fabric to fully penetrate, heat application should be provided at a temperature of 120 degrees. It can print in many colors. Any preferred print can be applied to the preferred surface at any time.

Perfect Appearance in Hot Foil Application

Preferred foil, gilding is done with options such as gold, silver and day metal. Cigarette boxes are used with the paper protection inside with the application of hot foil gilding. These can be transferred to other surfaces by temperature and pressure to create a beautiful display. It consists of very shiny metal layers containing an important carrier film. Gilding plays a very important role in the production of luxury cardboard packaging. For this reason, the usage area is also humid. Depending on the application method, first of all, adhesive is applied to the fabric. The preferred adhesive should be transparent. MC Cellophane Printing Packaging can prepare in a short time thousands of printing types for contract gilding products. In the printing type, which has a striking appearance, the foil gives an important functionality.

We offer many alternatives for hologram, plain and patterned works. In this way, it allows a beautiful, stylish image. It is also among the transactions that can be done without gold. But no foil was used in between. This is how the relief printing used today is carried out. In the language of printing, this is called relief printing. Every process is exactly the same, only gilding is not used, colorless and embossed texts can also be read. However, it is generally used to address the envelope with capital letters and to use less text. As there are many printing types, the most common usage area is foil gilded printing.

Printing types are covered in a very broad concept. Clothing products are a common print subject. It offers the most common use in invitations and many other products. In this way, the difference between less writing and foil printing is greater than the others. In printing, attention should be paid to the details of color tonnage, printing speed, and paper selection. We provide services in many areas as MC Cellophane Printing and Packaging industry. It has a wide range of uses such as institutions, hotels, restaurants.

visit our FACEBOOK page for more information

Return to the Homepage